Paint option -

is unique automated painting system which completely integrates all components for a turn-key solution. A difficult problem for painting equipment customers is system integration — making all the components work together.

is the solution for medium to high volume painting of panels.

Description

- Fully integrated turnkey system for 1-color painting of panels

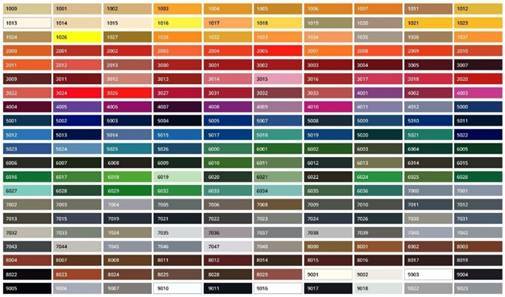

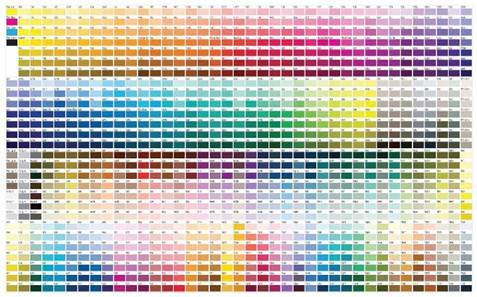

- RAL or Pantone colors (both available as an option)

- Fully automatic system with minimal labor

- High production rate up to 600 lm per hour

- Paint thickness: 60 – 70 microns wet and 30 – 35 microns dry

- Minimal space required compared to typical spray painting enclosures

- Suitable for painting other flat items similar to door panels

Panel Dimensions

- Length: 1.500 - 14.000 mm

- Height: 100 - 700 mm (≤ 2.000 mm optional)

- Thickness: 10 - 100mm (> 100 mm optional)

Advantages & Benefits

All users:

- Increase sales, profits and market share

- Offer the full range of RAL and/or Pantone colors

- Offer all panel styles in all colors — residential and industrial

- No special worker skills required

- Minimal labor requirements

- Low painting cost

- No minimum order requirements for customers

- Fast production and drying time

- Increase sales and income by painting other materials similar to door panels

- Add the axlacquer box option for spray application of lacquer to increase resistance to corrosion, fading and scratches

Panel Manufacturers

- Substitute low volume panel manufacturing for a specific color by painting galvanized or white panels

- Eliminate rarely used color steel coil inventory

- Reduce costs by painting panels made from coils without paint finish (only galvanization + primer)

- Use steel coils with incorrect colors — repaint panels at low cost

Door Assemblers

- Reduce panel inventory for many panel style / color combinations

- Eliminate panel inventory for rarely used panel style / color combinations

Offer the full range of RAL and/or Pantone colors

System Components

- computer management system

- Fully enclosed painting enclosure

- Robotic spray head manipulator

- Paint mixing unit: 2 components - base and hardener

- Color mixing unit using 7 – 16 colors yo create RAL or Pantone colors

(optional – some customers already have a mixing unit) - High pressure piston pump system for air supply

- Ventilation system with intake and exhaust filters

- Water filtration system

- Panel conveyors to and from the painting enclosure: length up to 15 m each

- axlacquer box for spray application of lacquer (optional)

- Automatic computer controlled panel racking system (optional)

- Recommended for volume painting

Note: The racking system for lacquer drying can be used - Drying room (not included)

Note: The drying room for lacquer can be used

Production Rates

- Cleaning time between color changes: ≈ 5 minutes

- Start-up time: ≈ 5 minutes

- Shut-down time: ≈ 5 minutes

Garage Doors Example: Every Door a Different Color

- Average European garage door has a 4.000 mm width with 4 panels

- Total panel length: 4 m x 4 panels = 16 lm

- Painting time: 16 lm / 10 lm per minute = 1,6 minutes

- If every door is a different color, 5 minutes for cleaning between each door

- Total time for one door: 6,6 minutes

- Production per hour: 9 doors (144 lm)

Logistics Doors Project Example: 30 Doors All the Same Color

- Logistic door dimensions: 3.500 x 3.500 mm with 6 panels

- Total panel length: 3,5 m x 6 = 21 lm

- Painting time: 21 lm / 10 lm per minute = 2,1 minutes

- If the logistics doors all have the same color, 5 minutes for cleaning after the 30 door job

- Total production time: (30 doors x 2,1 minutes) + 5 minutes = 68 minutes

- Total time for one door: 2,3 minutes

- Production per hour: 26 doors (546 lm)

Max Painting Production Rates |

|||

|

Per Minute |

Per Hour |

Per 8-Hour Shift | |

|---|---|---|---|

|

Panels: 100 – 610 mm |

10 lm |

600 lm |

4.800 lm |

|

Panels: 500 mm |

5,00 m2 |

300 m2 |

2.400 m2 |

|

Panels: 610 mm |

6,10 m2 |

366 m2 |

2.928 m2 |

Labor and technical details

Labor Requirement

- Only one worker is required to operate the system:

- Cleaning the system when changing colors

- Quality control of inbound panels

- Overall quality control

- Depending on the production volume and panel lengths, additional workers may be required for loading and unloading panels (automated handling optional)

Painting and Labor Comments

- Spray painting panels requires quality work with attention to detail

- Spray painting is unpleasant, boring and hazardous work

- Workers must wear protective clothing and respirator masks, which are hot and uncomfortable to wear

- There are many health hazards from long-term paint exposure

- Door companies have difficulty keeping painting workers

- High pay for workers is often not a solution — auto painting jobs typically pay more.

- The system eliminates spray painting labor and requires no special skills

Technical Details

- Solvent base paint (water base paint optional)

- Constant fluid flow rate

- Pulsation free system prevents spray pattern variation

- Fluid output: up to 2.000 cm3 per minute

- Unique pump changeover technology ensures consistent meteringand fluid flow rates

- Mixing accuracy +/- 1% due to the innovative pump changeover technology

- Continuous mixing auto-adjustment

- Injectmix technology allows injecting a custom catalyst volume into a continuous flow of base for best mixing quality

- Automatic component management: base and hardener

- Low air pressure: max 6 bar

- Volume of flushing solvent limited to real mixed material